Common Causes of Hydraulic Motor Failures and Solutions

Release time: 2025-10-16

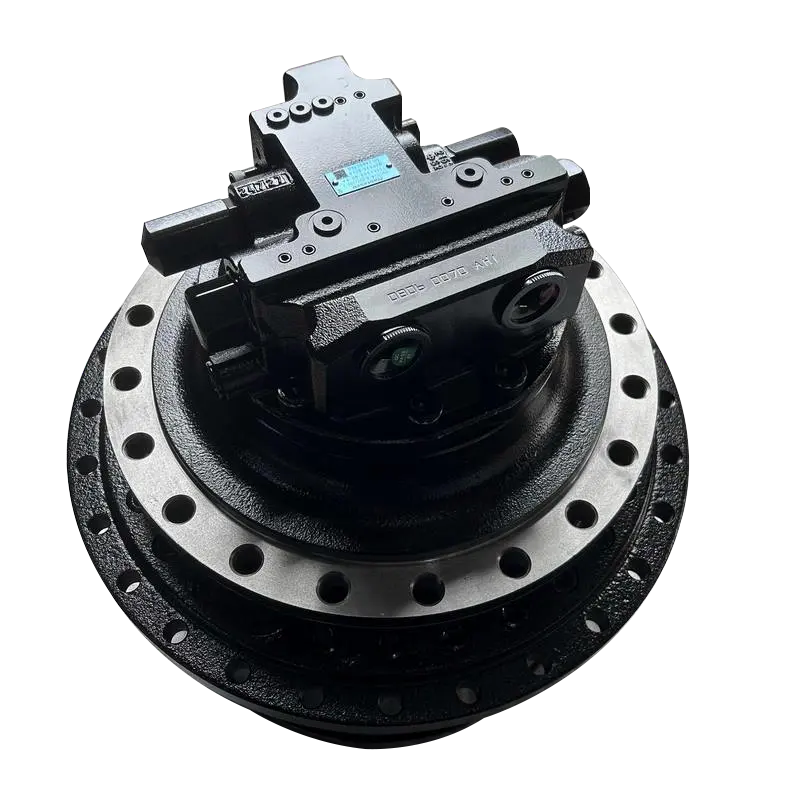

Hydraulic motors, as critical components in hydraulic systems, are widely used in various machinery and equipment. However, over time, hydraulic motors may experience failures that affect normal operations and reduce production efficiency. Understanding the common causes of hydraulic motor failures and their solutions not only improves the reliability of the equipment but also extends the lifespan of the hydraulic system.

Common Causes of Hydraulic Motor Failures

- Hydraulic Oil Contamination

- Cause: Hydraulic oil that contains impurities, such as dust, metal particles, or water, can cause damage to the friction components of the hydraulic motor, leading to reduced motor efficiency or complete failure.

- Symptoms: Increased noise, excessive vibration, or even the motor seizing up or operating erratically.

- Solution: Regularly check and replace the hydraulic oil, install filters to remove impurities, and maintain system cleanliness.

- Abnormal Hydraulic System Pressure

- Cause: Too high or too low pressure in the system can affect the normal operation of the hydraulic motor. Low pressure may fail to provide sufficient power, while high pressure may cause excessive wear or damage to internal components.

- Symptoms: The motor operates sluggishly, overload alarms trigger, or the motor may burn out.

- Solution: Regularly check the hydraulic system pressure to ensure it remains within the proper working range. Adjust the pressure valve as necessary.

- Excessive Hydraulic Oil Temperature

- Cause: High hydraulic oil temperature is often caused by system overload, poor heat dissipation, or pump malfunctions.

- Symptoms: Reduced motor efficiency, possible overheating, and even internal leakage.

- Solution: Check the system’s cooling devices and ensure the oil temperature stays within the optimal range. Avoid running the system under heavy loads for extended periods.

- Motor Bearing Damage

- Cause: Bearing damage may occur due to hydraulic oil contamination, insufficient lubrication, or prolonged overload operation.

- Symptoms: Abnormal sounds during operation, unstable motor speed, or even motor seizure.

- Solution: Regularly inspect the motor bearings and lubricate them as necessary. Replace damaged bearings in a timely manner.

- Motor Seal Failure

- Cause: The failure of internal seals or rubber sealing components in the hydraulic motor can lead to hydraulic oil leakage or air ingress into the system.

- Symptoms: Oil leakage, reduced motor efficiency, or system failure.

- Solution: Regularly inspect seals to ensure there are no leaks, and replace aged or damaged seals.

- Overloading or Frequent Starts

- Cause: Operating the hydraulic motor under excessive loads or frequent starts and stops can result in internal component wear and damage.

- Symptoms: Motor overheating, increased noise, and unstable operation.

- Solution: Design the system to prevent overloads, minimize frequent starts, and extend the motor’s lifespan.

Troubleshooting and Maintenance for Hydraulic Motors

- Regularly check the quality and oil level of the hydraulic oil. Use high-quality hydraulic oil when replacing, and ensure the oil level is correct.

- Periodically inspect and clean the filters to remove contaminants from the oil.

- Keep the hydraulic system pressure within normal operating ranges. Calibrate pressure gauges regularly to ensure stable system operation.

- Inspect the motor’s appearance and operational condition periodically. Stop the motor if any abnormal sounds or vibrations occur, and check for issues.

- Regularly clean the hydraulic system to remove internal contaminants and prevent long-term pollution.

Conclusion

Hydraulic motors are crucial components in hydraulic systems, and their stability directly impacts the overall performance of the system and the efficiency of the equipment. Therefore, promptly identifying and addressing hydraulic motor failures can improve production efficiency and reduce the risk of equipment downtime. By performing regular inspections and maintenance, you can ensure the hydraulic system remains in good condition, extend the lifespan of the equipment, and save on maintenance costs.

If you encounter hydraulic motor issues or require further maintenance support, feel free to contact Zhuri after-sales service team. We will provide you with professional solutions.