Excavator Hydraulic Motor Maintenance Guide: Ensuring Robust Power for Travel and Swing Systems

Release time: 2025-11-28

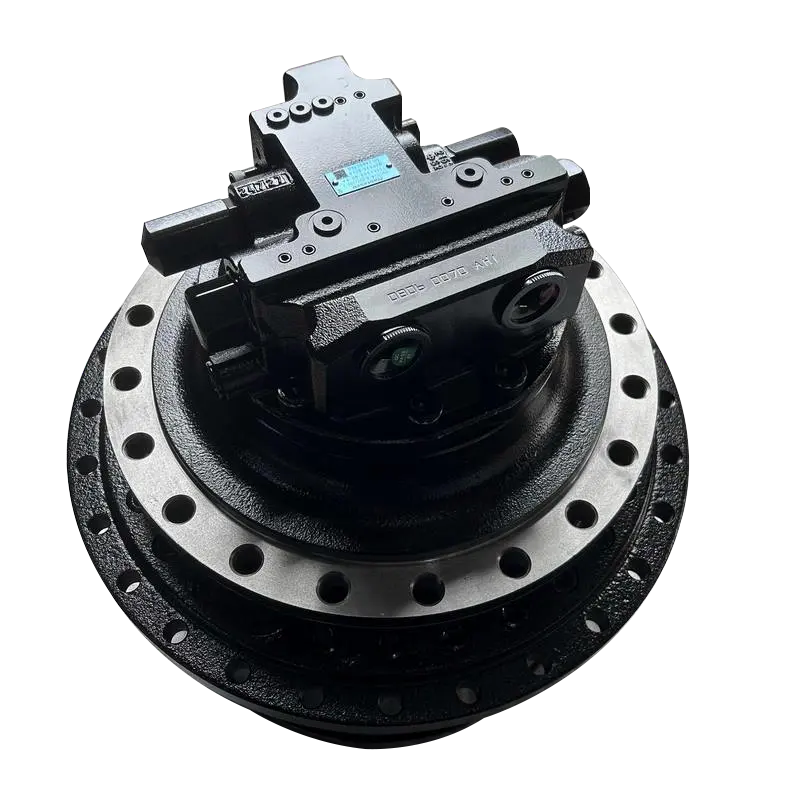

Excavator hydraulic motors, including the Motor de viagem and the Motor de giro, are critical components that enable the machine’s movement and operation. They operate under high pressure, heavy loads, and frequent impact in severe working conditions. Proper maintenance is essential not only for ensuring the excavator’s working efficiency but also for prolonging the machine’s overall lifespan and reducing costly downtime.

Core Maintenance Concept: Hydraulic Fluid Contamination Control

For excavator hydraulic motors, fluid contamination is the number one cause of failure. The motor’s precision components—such as pistons, swashplates, and valve plates—demand extremely high levels of fluid cleanliness.

- 1. Fluid Cleanliness is Paramount:

- Strict Adherence to Change Intervals: Replace hydraulic oil strictly according to the excavator manufacturer’s and the oil supplier’s recommended service intervals.

- Regular Fluid Analysis: Periodically draw hydraulic oil samples for particle counting (e.g., ISO 4406 standard) and moisture content analysis. If severe contamination is detected, replace the fluid immediately and identify the source of contamination, even if the scheduled interval has not been reached.

- Oil Adding Procedures: When topping up or replacing hydraulic fluid, always use refueling equipment with fine filtration, and never use dirty containers or funnels to pour oil directly into the tank.

- 2. Filter Element Replacement Management:

- Strictly replace all system filter elements (including the return line filter and pilot line filter) according to the maintenance manual. A clogged filter can cause the bypass valve to open, allowing contaminated oil to flow directly to the motor.

- 3. Breather Maintenance:

- Inspect the hydraulic tank breather. The breather balances the pressure inside and outside the tank; if it is clogged or damaged, external contaminants (dust, moisture) can enter the system.

Specific Checks and Maintenance for the Travel Motor

Travel motors bear the greatest risk of impact and contamination and require special attention.

- 1. Gear Oil Check and Replacement (Reducer Section):

- Function: Travel motors usually have an integrated planetary gear reducer. The gear oil for this section is separate from the hydraulic fluid.

- Interval: The gear oil must be changed at the specified interval (typically every few hundred hours), and checked for metal shavings.

- Procedure: Ensure the motor’s fill and drain plugs are correctly positioned during the oil change to prevent over-filling or under-filling.

- 2. Hoses and Connections:

- Inspect all high-pressure hoses connected to the travel motor for wear, aging, cracking, or severe bending. Hose failure can lead to sudden shutdown and significant fluid leakage.

- 3. Leak Inspection:

- Check for hydraulic oil or gear oil leakage at the connection between the travel motor casing and the wheel hub. Any shaft seal leak could be an early sign of high case pressure or internal wear.

Specific Checks and Maintenance for the Swing Motor

Swing Motors primarily focus on gear lubrication and braking performance.

- 1. Braking Performance:

- Check the performance of the swing brake (usually integrated within the motor or reducer). If there is abnormal coasting or shock during swing start-up or stop, it may indicate an issue with the brake or the swing cushion valve.

- 2. Gear Lubrication:

- Check the lubricant level and quality in the swing reducer. Regularly change the lubricant to ensure the motor’s output pinion and the slew bearing ring gear are adequately lubricated.

- 3. Case Pressure and Drain:

- Ensure the swing motor’s drain line is unobstructed. Restricted drainage can lead to excessive case pressure, damaging the shaft seal and potentially affecting the motor’s internal distributing components.

Troubleshooting and Prevention (Excavator Focus)

| Failure Symptom | Potential Cause (Excavator Specific) | Prevention and Solution |

| Drifting/Deviation During Travel | Inconsistent internal wear of travel motors (side-to-side) | Compare the case drain flow of both travel motors. |

| Weak Travel Power/Slow Speed | Failure in the pump’s power control system (insufficient oil supply) | First check the hydraulic pump’s power matching system and regulator. |

| Large Shock During Swing Start/Stop | Improper setting or damage of the swing cushion/relief valve | Check and adjust the safety relief valves in the swing hydraulic circuit. |

| Abnormal Motor Overheating | Prolonged high-load operation, insufficient hydraulic oil cooling | Check if the hydraulic oil cooler (fins) is clean and the fan is working properly. |

Summary of Key Maintenance Principles

- Separate Lubrication: Strictly differentiate between hydraulic oil (system) and gear oil (reducer); they must never be mixed or cross-contaminated.

- Immediate Shutdown: When signs of sluggish movement, abnormal noise, or overheating occur, stop the machine immediately and have the fault diagnosed by a qualified technician.

- Use Genuine Parts: Always use original or recommended high-quality filter elements and seal kits that are designed to withstand the high-stress conditions of construction machinery.

Zhuri-machinery specialize in providing genuine parts for hydraulic motors used in Sany and Hitachi excavators, ensuring your equipment always operates at its best. For any needs regarding routine maintenance, troubleshooting, or parts replacement, please feel free to contact our team of technical experts.