Falhas comuns em escavadeiras e soluções

Release time: 2025-08-30

Excavators are essential equipment in construction projects, directly affecting work efficiency and safety. Extended periods of high-intensity operation can lead to various malfunctions. Timely diagnosis and repair are crucial to maintaining the normal operation of the equipment. This article covers common faults and solutions for the six core systems of an excavator, including the engine, hydraulic, electrical, transmission, work device, and travel device systems.

Table of Contents

Common Engine System Failures

1.Engine Won’t Start

- Causes: Low battery charge, clogged fuel system, starter motor failure, etc.

- Solution: Check battery voltage, clean the fuel filter, inspect the starter motor.

2. Engine Lacks Power

- Causes: Clogged air filter, fuel injection system failure, turbocharger damage, etc.

- Solution: Replace the air filter, calibrate the fuel injectors, replace the turbocharger.

3. Abnormal Engine Noise

- Causes: Bearing wear, excessive valve clearance, slipping belts, etc.

- Solution: Replace worn parts, adjust valve clearance, inspect the belt system.

Common Hydraulic System Failures

1. Hydraulic Oil Leakage

- Causes: Loose hoses, aging seals, scratched piston rods, etc.

- Solution: Tighten connections, replace seals, repair the cylinder.

2. Weak or Slow Hydraulic Movements

- Causes: Oil contamination, hydraulic pump wear, cylinder leaks, etc.

- Solution: Replace hydraulic oil, calibrate pump pressure, replace cylinder seals.

3. Hydraulic System Overheating

- Causes: Clogged oil cooler, improper oil viscosity, unloading valve failure, etc.

- Solution: Clean the cooler, replace hydraulic oil, repair the unloading valve.

Common Electrical System Failures

1. No Power or Partial Electrical Failures

- Causes: Battery switch not turned on, blown fuses, loose connections, etc.

- Solution: Check the battery switch, replace fuses, repair connections.

2. Instrument Panel Displays Abnormalities

- Causes: Sensor failure, poor circuit connections.

- Solution: Replace the sensor, inspect circuit connections.

3. Lighting System Failures

- Causes: Burned-out bulbs, faulty switches, broken circuits.

- Solution: Replace bulbs, repair switches, check circuits.

Common Transmission System Failures

1. Noisy Transmission or Difficulty Shifting Gears

- Causes: Low transmission fluid, clutch issues, electronic control failures.

- Solution: Replace transmission fluid, adjust the clutch, replace solenoids.

2. Drive Axle Leaking Oil or Overheating

- Causes: Damaged oil seals, insufficient oil, bearing wear.

- Solution: Replace oil seals, add proper oil, inspect bearings.

Common Work Device Failures

1. Stiff Movements or Inability to Operate

- Causes: Worn pins, damaged cylinders, stuck valve cores, etc.

- Solution: Replace pins, repair cylinders, clean valve cores.

2. Insufficient Excavator Bucket Force

- Causes: Cylinder seal leakage, deformed connecting rods, hydraulic system issues.

- Solution: Replace cylinder seals, repair connecting rods, adjust hydraulic system.

Common Travel Device Failures

1. Steering Issues or Inability to Move

- Causes: Uneven track tension, faulty travel motor, stuck stroke control valve.

- Solution: Adjust track tension, replace travel motor, clean valve cores.

2. Abnormal Noise or Vibration

- Causes: Damaged drive wheel bearings, worn tracks, faulty travel motors.

- Solution: Replace bearings, repair tracks, inspect travel motors.

Conclusão

Maintaining an excavator requires regular maintenance and timely troubleshooting. Understanding and mastering common faults and solutions can help extend the equipment’s lifespan and improve work efficiency. Regular inspections and proper maintenance are key to preventing unexpected breakdowns and ensuring the equipment runs efficiently and stably.

If you want to know more about excavator parts, please contact zhuri-machinery.

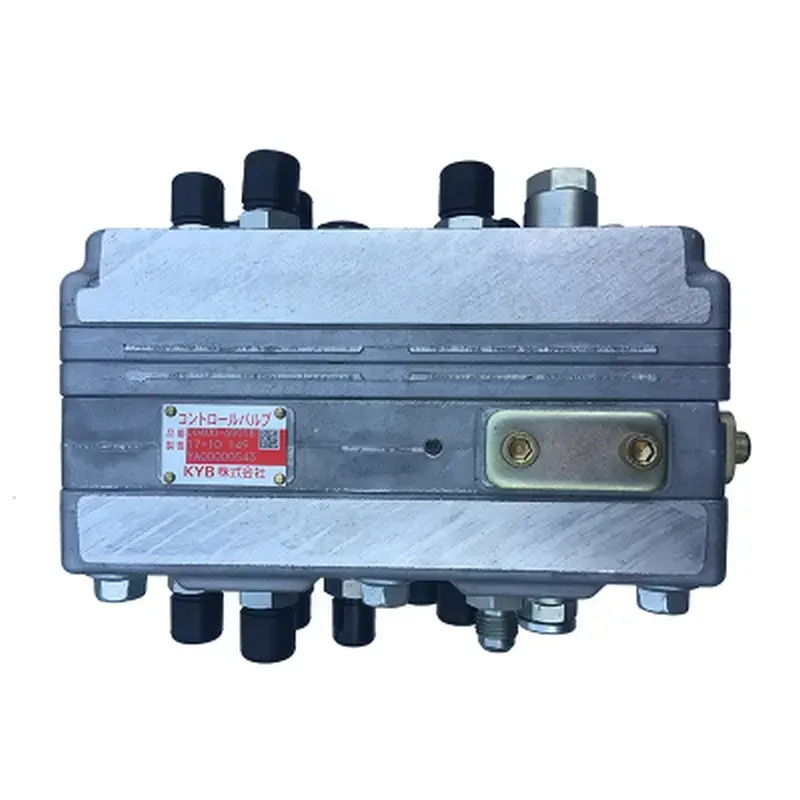

As authorized distributors of numerous renowned brand products, the full range of original HITACHI excavator parts can ensure that HITACHI excavators operate at their best performance levels, fully living up to the brand’s long – standing reputation for reliability. The original SANY excavator parts are celebrated for their high – precision manufacturing processes and excellent quality. We also supply ISUZU engine parts, which are widely acknowledged for their powerful output and remarkable durability. Our product offerings further include products from Hengli Hydraulics, DEKA Hydraulics, and NGC gearboxes, providing advanced hydraulic solutions; SAKURA filters, which effectively protect equipment; and Chevron lubricants, which achieve optimal lubrication performance… Furthermore, we offer undercarriage parts sourced from DCF, a South Korean brand, along with HLD and CHT, leading Chinese brands. These parts are of great significance for the stable operation and mobility of excavators.